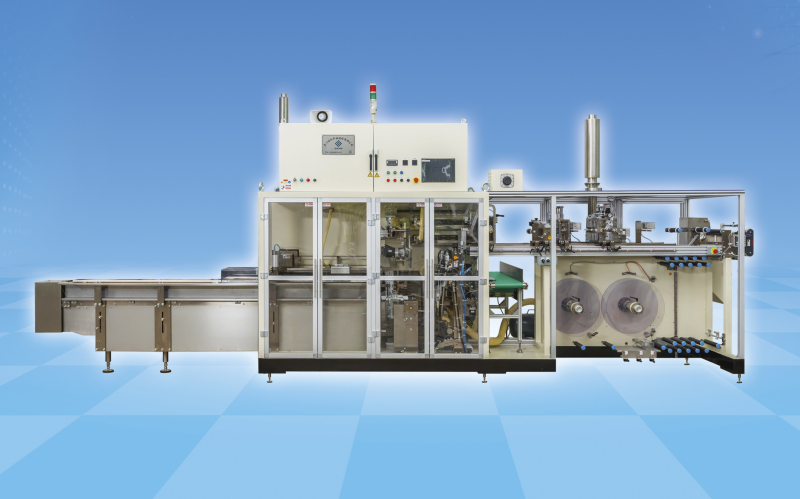

Roll-film sanitary napkin packaging machine

Why choose GACHN

1.Technology-oriented: GACHN has a technical and R&D team of more than 40 personal

2.Gachn Technology has been used to package more than 60 sanitary napkin brands both in China and internationally.

3.Gachn's sanitary napkin packaging machine have helped the biggest sanitary napkin producer in China capture more than 40% of market share in China.

4.More than 20 years of designing and manufacturing experience in hygienic business.

- GACHN

- CHINA

- 3 MONTHS

- 400 SETS/YERA

- Information

The roll-film sanitary napkin packaging machine is designed for high-efficiency, fully automated packing of sanitary pads using continuous roll film. It delivers stable sealing quality, precise cutting, and fast production speed, making it ideal for hygiene product manufacturers seeking cost-effective and reliable packaging solutions.

Description

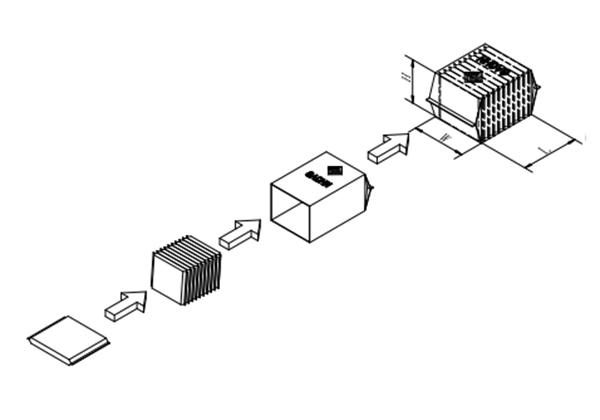

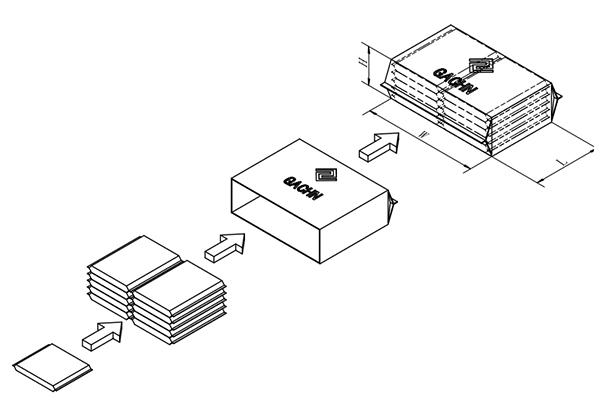

one stack sanitary pad packaging

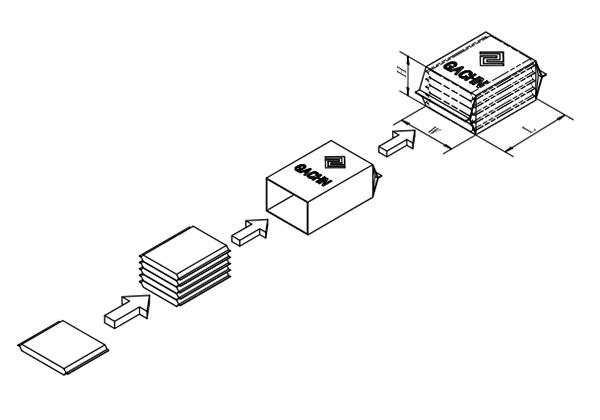

one stack sanitary pad packaging

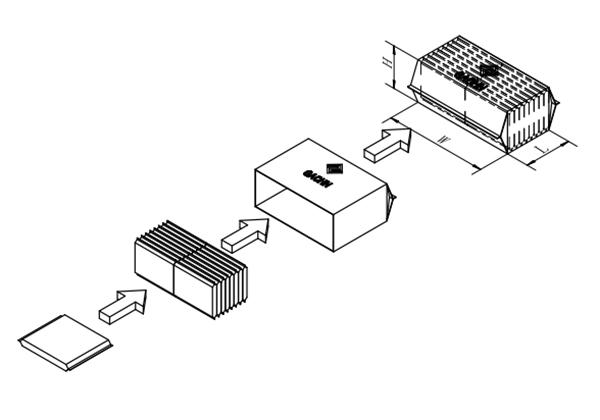

two stacks sanitary pad packaging

double-stacked sanitary pad packagingTechnical parameter

| Packaging speed | 110-120 packets/min |

| Production efficiency | ≥95% |

| Finished product ratio | ≥98% |

| Sanitary pad's measurement | Based on customer's requirement |

| Single layer package's thickness | 40~70μm |

| Number of sanitary pad it arranges | 5~20pieces |

| Packaging material | PE film, aluminum coated film, composite film |

| Packaging method | Roll bag or pre-made bag; Vertically or horizontally |

Special features

1. The packaging machine seamlessly integrates with the mainframe, allowing for a fully automated operation that streamlines the packaging process and increases efficiency. This seamless connection ensures that there are no interruptions or delays in the production line, leading to a more consistent output of packaged products.

2. While utilizing the full servo technique enables the machine to operate at a faster speed, it also prioritizes packaging accuracy and stability. This means that manufacturers can achieve higher productivity without sacrificing the quality of their packaged products, ultimately leading to greater customer satisfaction and trust in the brand.

3. The inclusion of interchangeable components not only enhances convenience during operation but also simplifies maintenance procedures. By being able to easily swap out components as needed, downtime is minimized and overall equipment effectiveness is improved, resulting in cost savings for manufacturers.

4. With an automated system handling the arranging, stacking, and packaging of sanitary pads, manual force is completely eliminated from these processes. This not only reduces labor costs but also ensures consistency in product presentation and minimizes potential errors that may occur when relying on manual labor for these tasks.

Optional Add-Ons:

Date/Batch coding system

Easy-tear notch forming device

Multi-line packaging configuration

Online product inspection (weight, size, metal detection)

Automatic cartoning line connection

Applications:

Sanitary napkin manufacturers

Feminine hygiene product factories

OEM/ODM hygiene product brands

High-volume automated packaging lines