High speed sanitary napkin counting stacker

Why choose GACHN

1.Technology-oriented: GACHN has a technical and R&D team of more than 40 personal

2.Gachn Technology has been used to package more than 60 sanitary napkin brands both in China and internationally.

3.Gachn's sanitary napkin packaging machine have helped the biggest sanitary napkin producer in China capture more than 40% of market share in China.

4.More than 20 years of designing and manufacturing experience in hygienic business.

- GACHN

- CHINA

- 3 MONTHS

- 400 SETS/YERA

- Information

High Speed Sanitary Napkin Counting Stacker

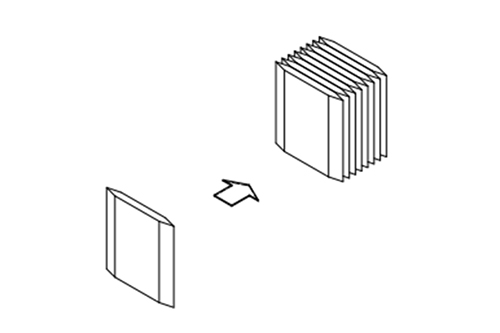

The High Speed Sanitary Napkin Counting Stacker is an advanced auxiliary machine designed to accurately count, stack, align and transfer sanitary napkins at high speed. It is typically connected to a sanitary napkin production line or flow-wrap packaging machine, helping manufacturers increase efficiency, reduce manual labor, and maintain strict hygiene standards.

This stacking system series is suitable for stacking sanitary napkins with a 3~12mm single layer thickness. It can arrange 5~20 pieces for stacking and its designed stacking speed is 1600 pieces/minute.

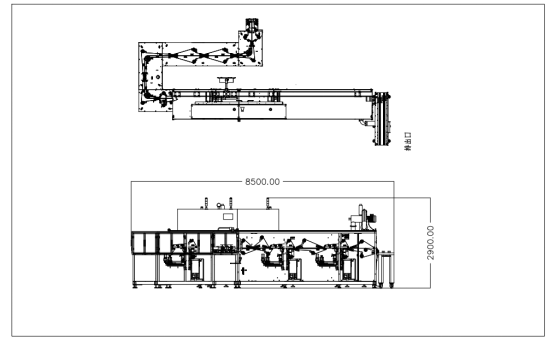

Technical parameter

| Designed speed | 1600 pieces/minute |

| Stabilized speed | 1200 pieces/minute |

| Installed capacity | 14kw |

| End product's measurement | 3~12mm |

| Number of sanitary pad it arranges | 5~20 pieces |

| Machine's measurement | 2.6(L)*2.8(W)*2.4(H)m |

| Weight | Approximately 2900kg |

Key Features

1. High-Speed, Stable Counting

Engineered for large-volume production environments:

Running speed up to 800–1200 pcs/min (model-dependent)

Accurate counting with minimal error rate

Supports various pad sizes and thicknesses (day-use, night-use, ultra-thin, winged pads)

2. Precise Stacking & Neat Alignment

The machine neatly arranges sanitary napkins into uniform stacks, ensuring:

Smooth transfer to packaging machines

Consistent pack appearance

Reduced product deformation and wrinkling

Stack height can be adjusted according to packing requirements.

3. Servo-Driven Precision Control

Advanced servo motors ensure synchronized motion throughout:

High-accuracy feeding

Smooth pad separation

Stable stacking without jamming

Ideal for premium sanitary pad packaging lines.

4. Easy Size Changeover

Quick adjustment for:

8 pcs / 10 pcs / 20 pcs / 40 pcs stacks

Different pad lengths and thicknesses

OEM pad specifications

Tool-free or low-tool changeover improves production flexibility.

5. Hygienic & Safe Machine Structure

Designed for feminine hygiene factories with strict cleanliness requirements:

Stainless steel and aluminum alloy construction

Dust-proof enclosure option

Easy-to-clean surfaces

Ensures safe handling of sanitary products.

6. User-Friendly Touchscreen Control

Multi-language HMI

Recipe storage for different stack formats

Real-time monitoring of speed, count, alarms

Diagnostic functions to reduce downtime

7. Seamless Integration with Packaging Lines

Compatible with multiple downstream equipment:

Roll-film flow wrap packaging machines

Premade bag packaging machines

Automatic cartoners

Multi-line production setups

Provides stable, continuous feed for automated packing.

Special features

1. The stacking quantity is same as the quantity of the package bags marked on.

2. There is no pads dropped down at the process of products transporting

3. The products should not damaged,drape and folded.

4. In three years, because of the electrical equipment software upgrade, the supplier will provide free technical support.

5. The equipment warranty period of one year, under the premise of strict accordance with the supplier to provide instructions to operate, due to the supplier design or manufacturing defects cause to equipment damaged, and the supplier is responsible for the damaged parts to be timely free repaired or free charge replacement parts, for a free replacement in necessary.