Intelligent Electrical Integration Enhances Automation and Reliability

2025-12-11 20:00Intelligent Electrical Integration Enhances Automation and Reliability

As automated manufacturing evolves, the electrical integration stage has become a defining factor in the performance of modern packaging equipment. At Xiamen Gachn Technology Co., Ltd., intelligent electrical engineering is a core strength, enabling every sanitary napkin packing machine, Wet Wipe Production Line, Diaper Packing Machine, diaper packaging machine, and sanitary pad packaging machine to operate with precision, stability, and high-speed coordination.

Gachn’s electrical engineering team consists of experienced automation specialists who have spent years optimizing the control systems used in high-speed hygienic product packaging. During electrical assembly, each sanitary napkin packing machine and sanitary pad packaging machine is equipped with a multi-axis servo drive system. These advanced servo motors provide precise movement control for feeding, wrapping, sealing, and stacking. At high production speeds, where milliseconds matter, this servo-driven architecture ensures smooth synchronization between every mechanical component.

For the Wet Wipe Production Line, electrical integration is even more sophisticated due to its multi-module structure. The line includes unwinding units, slitting and folding modules, lotion-application pumps, and flow-wrapping sections—all requiring exact coordination. Gachn’s automation engineers develop specialized PLC programs that ensure all modules communicate seamlessly. Each Wet Wipe Production Line features dynamic tension control, temperature monitoring, and automated speed adjustment to prevent material stretching, wrinkling, or misalignment during continuous operation.

The Diaper Packing Machine and diaper packaging machine models also rely heavily on intelligent electrical systems. These machines must handle diverse product sizes across baby and adult diaper categories. Gachn engineers integrate preset parameter systems that allow operators to switch between sizes quickly. Through touchscreen HMI interfaces, operators can adjust folding dimensions, sealing pressure, feeding speed, and conveyor timing with ease. This flexibility makes the diaper packaging machine highly efficient for factories managing multiple SKUs.

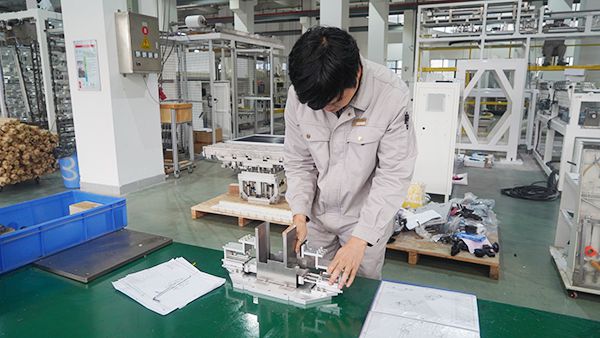

During electrical integration, every sanitary napkin packing machine and sanitary pad packaging machine undergoes rigorous control panel assembly. Gachn uses industrial-grade components sourced from globally recognized brands to ensure long-term stability. Each wire is routed through flame-retardant conduits, and cable trays are designed to minimize electromagnetic interference. This level of detail reduces system faults and enhances reliability in 24-hour production environments where downtime directly increases operational costs.

Electrical safety is another fundamental aspect. Each Wet Wipe Production Line, sanitary napkin packing machine, and diaper packaging machine is equipped with multi-level safety sensors, including emergency stop buttons, door interlocks, temperature overload protections, and motor monitoring functions. These systems safeguard operators and maintain production stability. Gachn applies CE and ISO-compliant safety standards, ensuring the sanitary pad packaging machine and Diaper Packing Machine models meet international certification requirements.

The integration process also includes software-level calibration. Engineers test each servo motor’s acceleration curve, torque limit, and braking system. For sanitary napkin packing machine models, sealing temperature control is fine-tuned to match specific film materials. For the diaper packaging machine, pushers and clamps are synchronized with conveyor motion to prevent misfeeds. In Wet Wipe Production Line testing, lotion pump dispersion and folding blade timing are optimized for accuracy and consistency.

After initial integration, the machine enters the electrical debugging phase. Engineers activate each axis step by step to inspect motor function, sensor signal accuracy, temperature readings, and electrical noise levels. For the sanitary pad packaging machine and sanitary napkin packing machine, film feeding sensors and photocell tracking systems are tested under various lighting conditions to ensure stable positioning. For the Diaper Packing Machine, vacuum suction modules and alignment sensors are calibrated to achieve precise product handling.

Each machine undergoes a full-cycle simulation where engineers mimic high-speed production. Wet Wipe Production Line systems run through tension fluctuations and cutting cycles; sanitary napkin packing machine models run through sealing speed variations; diaper packaging machine units are tested with different product sizes to validate compatibility. These tests ensure that every sanitary pad packaging machine and Diaper Packing Machine performs flawlessly before moving to mechanical testing and final factory acceptance.

By the time electrical integration is complete, each sanitary napkin packing machine, Wet Wipe Production Line, Diaper Packing Machine, diaper packaging machine, and sanitary pad packaging machine has undergone hundreds of precision checks. This ensures consistent output quality, stable long-term performance, and minimized maintenance requirements.

Electrical integration is not just a technical step at Gachn—it is a commitment to delivering intelligent, reliable, and globally competitive machinery. Through advanced control systems, world-class automation technology, and rigorous debugging, Gachn ensures that every machine shipped worldwide supports high-speed, high-accuracy, and worry-free production for international hygienic product manufacturers.