How to Choose a High-Capacity Sanitary Napkin Packaging Machine for Large-Scale Production

2025-09-01 20:00How to Choose a High-Capacity Sanitary Napkin Packaging Machine for Large-Scale Production

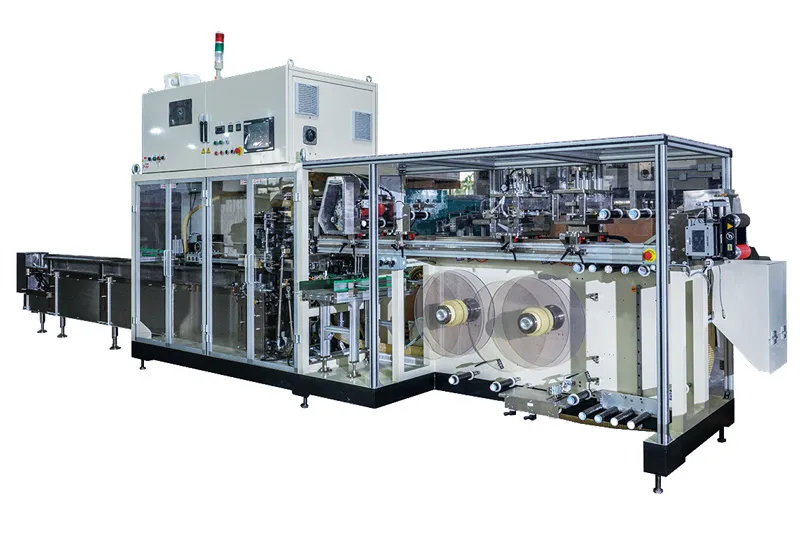

For factories looking to scale up sanitary napkin production, selecting the right sanitary napkin packaging machine is a critical decision. The ideal equipment not only ensures high output but also guarantees consistent product quality and operational efficiency. Xiamen Gachn Technology Co., Ltd., a leading name in the disposable hygiene machinery market, offers valuable insight into what manufacturers should consider.

Founded in 2011 by a group of former college classmates with over 20 years of experience in research and development, Gachn has become a trusted supplier of automated bag packaging machines. The company integrates R&D, production, marketing, and OEM/ODM services, providing comprehensive solutions for hygiene product manufacturers worldwide.

One of the key considerations when choosing a high-capacity sanitary napkin packaging machine is production efficiency. Factories need sanitary napkin packaging machines capable of handling large volumes without frequent stops or adjustments. Gachn sanitary napkin packing machines are designed for continuous operation, ensuring steady output that can meet growing market demands.

Another important factor is packaging quality and consistency. sanitary napkin packaging Machines must seal products securely, maintain uniform packaging dimensions, and accurately print batch numbers and expiration dates. This ensures that end products are visually appealing and compliant with industry standards. Gachn’s machines are engineered to deliver precise, reliable performance, reducing waste and improving overall production quality.

Maintenance and operational stability are equally critical. High-speed production can stress machinery, so equipment that is durable and easy to maintain is essential. Gachn has invested heavily in modern intelligent manufacturing facilities, allowing their sanitary napkin packaging machines to run reliably while minimizing downtime and maintenance costs.

Modern sanitary napkin packaging packaging lines also benefit from automation and intelligent controls. Features such as automated counting, alignment correction, and real-time monitoring reduce manual labor requirements and improve overall workflow efficiency. Gachn’s intelligent systems provide operators with clear dashboards, fault alerts, and production analytics, helping factories optimize every stage of the packaging process.

Finally, choosing a supplier with strong credentials and responsive after-sales support can make a significant difference. Gachn’s extensive experience, significant investment in R&D, and global client base demonstrate its capability to provide both reliable sanitary napkin packaging machines and long-term service. Their OEM/ODM solutions offer flexibility to meet specific production requirements, ensuring that factories receive equipment tailored to their operational needs.

For sanitary napkin manufacturers aiming for large-scale production, selecting a high-capacity sanitary napkin packaging machine is not just about speed—it’s about reliability, quality, and intelligent operation. By partnering with experienced and innovative suppliers like Gachn, factories can scale efficiently while maintaining product excellence.