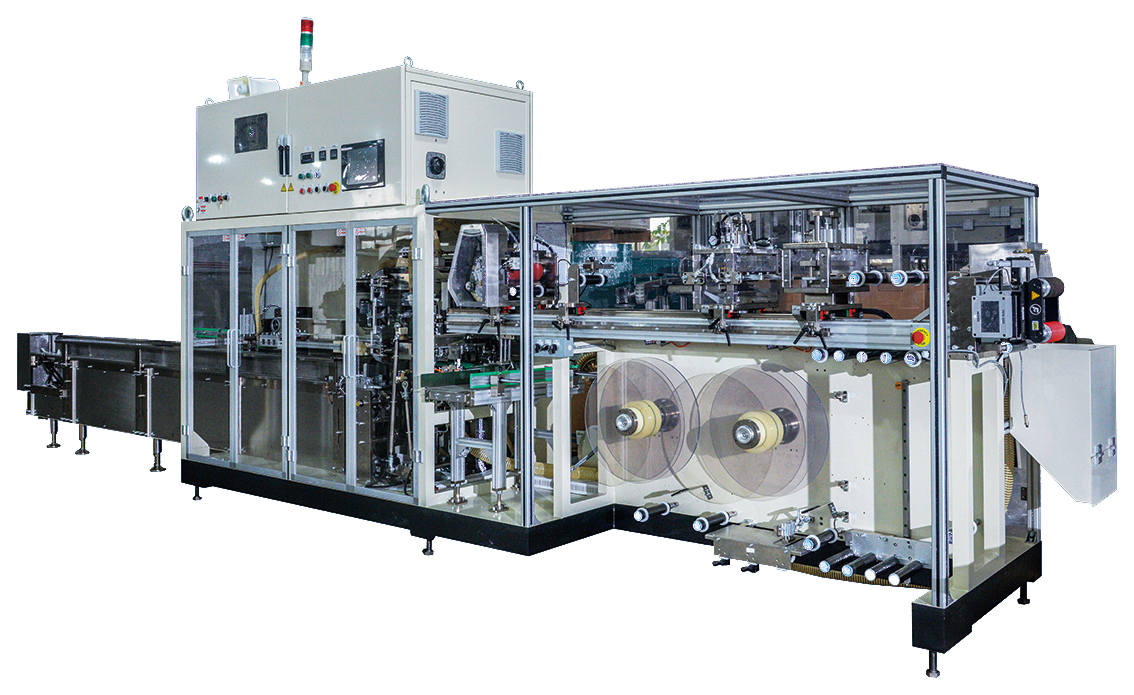

Sanitary Napkins and Panty liners Packaging Machine

Why choose GACHN

1.Technology-oriented: GACHN has a technical and R&D team of more than 40 personal

2.Gachn Technology has been used to package more than 60 sanitary napkin brands both in China and internationally.

3.Gachn's sanitary napkin packaging machine have helped the biggest sanitary napkin producer in China capture more than 40% of market share in China.

4.More than 20 years of designing and manufacturing experience in hygienic business.

- GACHN

- CHINA

- 90 WORKING DAYS

- 400 SETS/YERA

- Information

The Sanitary Napkins and Panty Liners Packaging Machine is an advanced automatic solution designed for the high-speed, hygienic, and precise packaging of feminine hygiene products. It supports individual wrap, multi-pack formats, and various pad thicknesses, enabling manufacturers to enhance production efficiency while ensuring superior product protection.

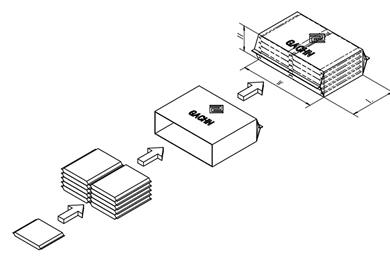

This packaging machine series packages the stacked sanitary napkins and panty liners into bags, then seals the bags. It will also produce the bags before packaging, with the packing material a printed film. Two rolls of printed film with one on and one off operational functions will not stop packaging when changing between either roll, ensuring this packaging machine has a high working efficiency. It will quickly switch between different product specifications, and is easy to operate.

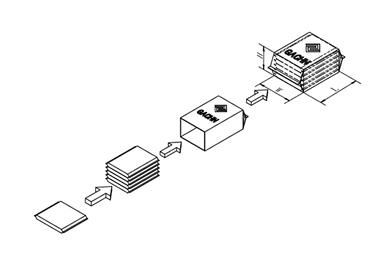

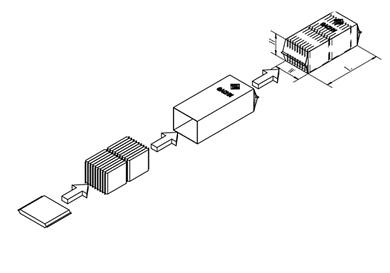

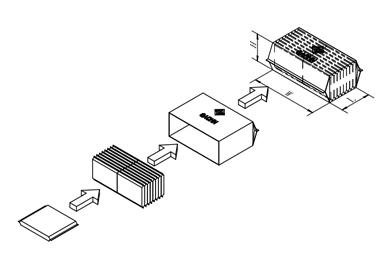

Schematic diagram of the package

Technical parameter

| Model: | GM-088W |

| Working speed: | Around 50- 60 bags/min (in relation to the application) |

| Packing bag type: | Tube roll film |

| Tube roll material: | PE film, composite film (single layer thickness:40~70um) |

| Packing type: | Landing type, Standing type |

| Machine dimension: | L6.3m×W1.5m×H2.0m(can be fine-tuning) |

| Installation capacity: | about 17KW |

| Power supply: | 3Ph4W(A、B、C、PE), 380V/50Hz, stable supply |

| Power supply: | ≤300LPM |

| Air supply: | 0.6-0.8MPa |

Special features

1. Gusset shaping unit ensures product stability and accuracy; gusset overlap deviation is less than 3mm.

2. Bag opening unit operates with bag package of different specifications, and the changing of specifications can be done by adjusting the parameters.

3. The roll unwinding unit runs continuously, while one roll is being used, a spare roll is inserted into the machine, enabling it to switch between rolls in a short time, thus the increasing working efficiency.

4. The height of the machine is adjusted through a device placed under it, enabling it to maintain its horizontal placement on uneven surfaces.

Key Features

1. High-Speed Automated Packaging

Engineered for large-volume production lines, the machine performs continuous feeding, film forming, sealing, and cutting with exceptional stability.

Speed range: 200–800 packs/min (model-dependent)

Suitable for day-use, night-use, ultra-thin, and thick sanitary pads

Supports both napkins and panty liners with quick size changeovers

2. Flexible Packaging Formats

Designed to meet diverse market needs:

Individual wrap packaging

Multi-piece outer bags

Compatible with PE film, laminated film, breathable film

Film width, sealing length, and bag depth can be adjusted via touch panel.

3. Servo-Driven Precision Control

Advanced servo motors ensure:

Accurate product positioning

Synchronized film feeding

High-accuracy cutting with minimal film waste

Ideal for brands requiring perfect pack appearance and consistent sealing.

4. Superior Sealing Quality

Adopts efficient constant-temperature heat sealing technology:

Neat and firm sealing

Leak-proof structure

Enhanced hygiene and extended shelf life

5. Hygienic & Safe Machine Design

Specially developed for feminine hygiene factories:

Stainless steel contact surfaces

Enclosed conveying channels

Anti-dust protective shields

Easy-to-clean modular design

Ensures compliance with strict hygiene requirements.

6. Intelligent Touchscreen Operation

User-friendly HMI allows:

Recipe storage for different pad sizes

Fault detection and alarm display

Real-time speed and temperature monitoring

Multi-language interface (English/Chinese/Spanish optional)

7. Low Maintenance & Energy Efficient

Optimized mechanical structure reduces wear and noise.

Long service life and low operating cost make it suitable for 24/7 continuous production.

Applications:

This machine is ideal for:

Sanitary napkin manufacturers

Panty liner production plants

Feminine hygiene OEM/ODM factories

High-speed automatic packaging lines

Brands focused on premium hygienic packaging