Premade Bag Packaging Machine for Pad and Pantyliner

Why choose GACHN

1.Technology-oriented: GACHN has a technical and R&D team of more than 40 personal

2.Gachn Technology has been used to package more than 60 sanitary napkin brands both in China and internationally.

3.Gachn's sanitary napkin packaging machine have helped the biggest sanitary napkin producer in China capture more than 40% of market share in China.

4.More than 20 years of designing and manufacturing experience in hygienic business.

- GACHN

- CHINA

- 3 MONTHS

- 400 SETS/YERA

- Information

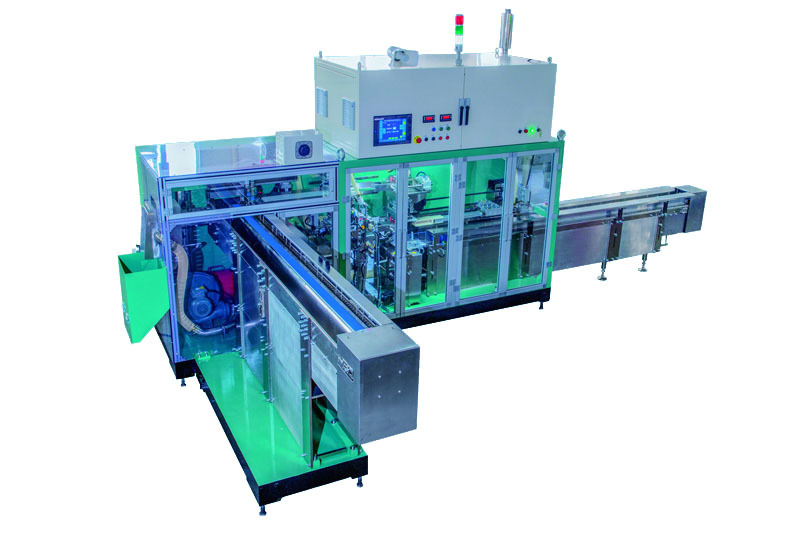

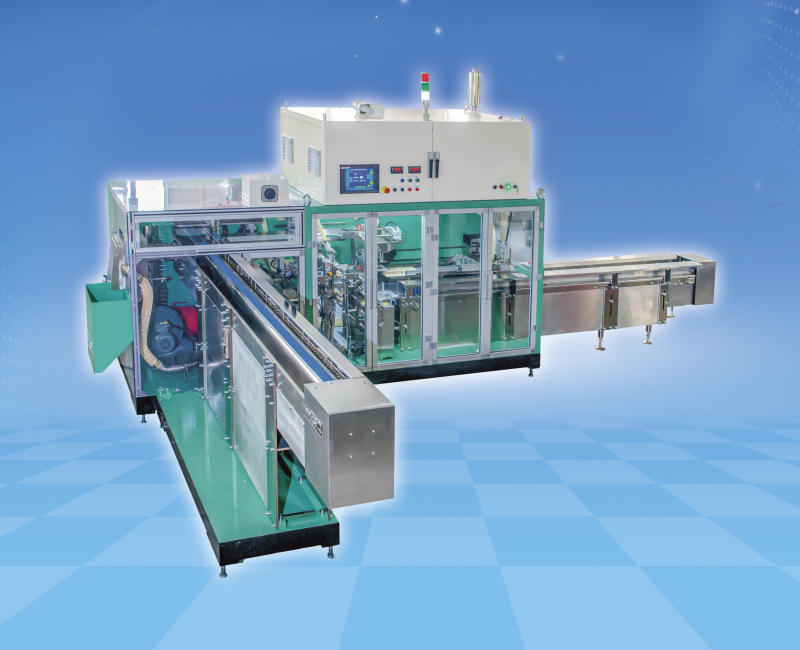

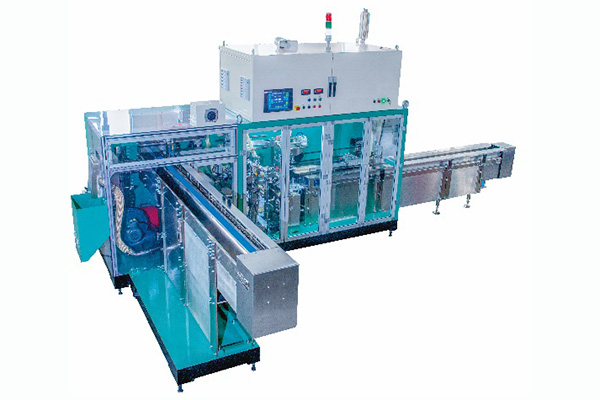

Premade Bag Packaging Machine for Pad and Pantyliner

Premade Bag Packaging Machine for Pad and Pantyliner

The Premade Bag Packaging Machine for Pad and Pantyliner is designed for fast, hygienic, and fully automatic packing of sanitary napkins and panty liners into preformed bags such as stand-up pouches, flat bags, zip-lock bags, and PE drawstring bags. It provides stable sealing, flexible bag compatibility, and precise filling—ideal for feminine hygiene manufacturers seeking premium retail-ready packaging.

Key Features

1. Compatible with Multiple Premade Bag Types

Supports various bag formats used in sanitary product packaging:

Stand-up pouch / doypack

Flat pouch

Zip-lock resealable pouch

Gusseted bags

PE / laminated premade bags

Bag size can be switched automatically or via quick mechanical adjustment.

2. Automated Bag Opening, Filling & Sealing

A fully servo-controlled system handles the entire packaging cycle:

Automatic bag pickup

Bag opening and shaping

Product filling (pads or pantyliners)

Heat sealing or zipper sealing

Finished bag discharge

Ensures consistent pack appearance and stable sealing quality.

3. Accurate Counting & Stacking System

Integrated high-precision counting device ensures correct quantities for:

8 pcs / 10 pcs / 20 pcs / 40 pcs packs

Custom OEM multipacks

Perfect for brands requiring accurate retail packaging.

4. Hygienic Design for Sensitive Products

Developed specifically for feminine hygiene factories:

Stainless steel contact surfaces

Enclosed feeding channel

Dust-proof protective covers

Smooth, easy-clean design

Complies with global hygiene standards.

5. High-Speed and Stable Operation

Typical output: 20–60 bags/min (depending on bag type & product size)

Servo motors ensure smooth motion, precise bag control, and reduced downtime.

6. User-Friendly Touchscreen Control Panel

Multi-language interface

Packaging recipes for different bag sizes

Fault detection & alarm display

Real-time monitoring of temperature, vacuum, sealing and speed

Beginner-friendly design reduces training time.

7. Lower Film & Material Waste

Since premade bags are used, the machine eliminates roll-film trimming waste, helping reduce cost and improve environmental performance.

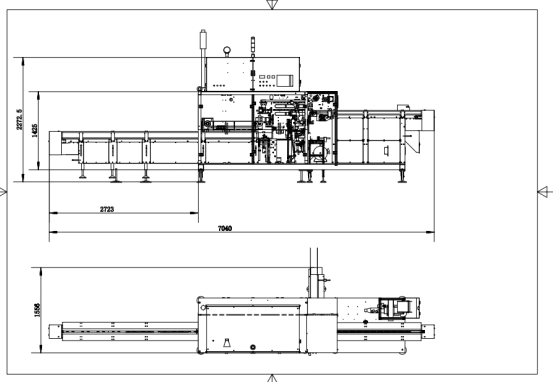

Technical parameter

Model: GM-088WY

Working speed: up to 55 bags/min(in relation to the application)

Yield rate: ≥98%

Packing bag type: pre-made bags on wickets

Packing material: PET, composite film (single layer thickness:40~70um)

Packing type: laying,upright

Stacking height: ≤90mm

Machine overall size:L6.3m×W1.5m×H2.0m(in relation to the application)

Weight:: about 2500kg

Installation capacity: about 16KW

Power supply: 3Ph4W(A、B、C、PE), 380V/50Hz

Air supply: 0.6-0.8MPa

Air consumption: ≤300LPM

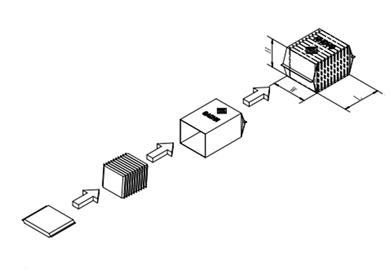

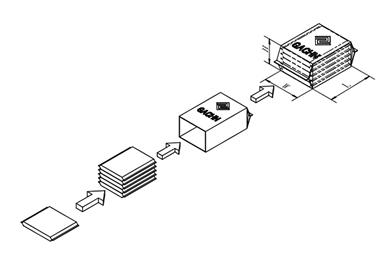

Schematic diagram of the package

Special features

Gusset shaping unit ensures product stability and accuracy; gusset overlap deviation is less than 3mm.

Bag opening unit operates with bag package of different specifications, and the changing of specifications can be done by adjusting the parameters.

When the machine running, any doors cannot open, unless press the emergency stop button or blackout, the door can open.

Simple operation, hommization, the important parameters with password protection.