Revolutionizing Hygiene: Fully Automatic Sanitary Napkin Packaging Machine Ensures Safety and Zero Contact

2025-05-18 20:00Revolutionizing Hygiene: Fully Automatic Sanitary Napkin Packaging Machine Ensures Safety and Zero Contact

In today’s hygiene-conscious world, consumer demand for safety, cleanliness, and efficiency in personal care products has never been higher. Among these products, sanitary napkins hold a crucial role in the daily lives of millions of women worldwide. Ensuring their hygienic integrity during production and packaging is paramount—not only for regulatory compliance but also for consumer trust. This is where the fully automatic sanitary napkin packaging machine emerges as a transformative innovation in the hygiene product industry.

Unlike traditional semi-automatic systems that involve human contact, modern sanitary napkin packaging machines are designed to offer zero-contact solutions from start to finish. These systems integrate advanced automation to handle the packaging process seamlessly, ensuring that the sanitary napkins remain untouched, clean, and completely safe until they reach the end user. The automated process eliminates any risk of contamination, which is vital in a product directly associated with personal health and wellness.

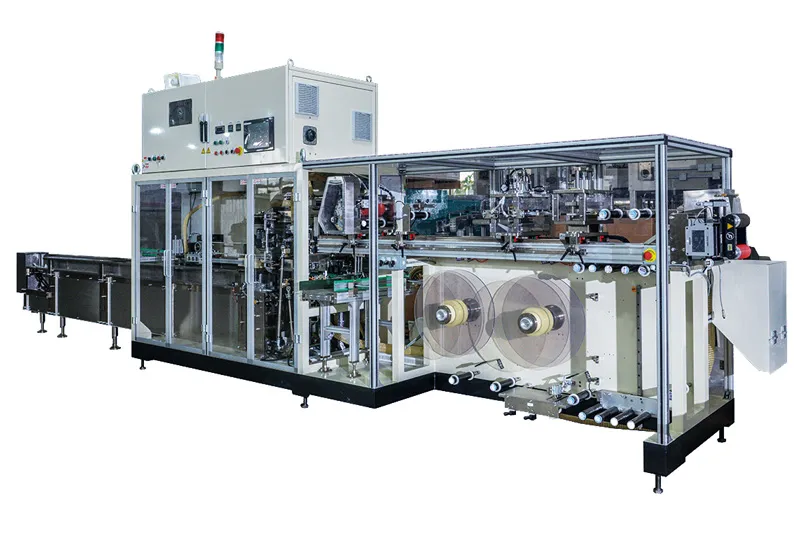

The Gachn fully automatic sanitary napkin packaging machine is equipped with intelligent sensors, servo-driven motion control, and precision alignment systems to handle delicate materials with exceptional accuracy. The process begins immediately after the production line, where napkins are automatically aligned, stacked, wrapped, sealed, and counted—all without the need for manual handling. This approach guarantees uniformity in packaging and minimizes material waste, while also drastically increasing production efficiency.

Gachn Another key benefit is the ability of these machines to support high-speed operation without compromising hygiene or quality. With customizable packaging options including pillow packs, flow wraps, or grouped bundle packs, the system can meet varying demands from global markets, retail chains, and private label brands. This versatility makes the machine ideal not only for large-scale manufacturers but also for businesses looking to scale sustainably and responsibly.

In addition to improving hygiene and speed, these machines reduce labor dependency and human error, leading to cost savings and a lower risk of operational disruption. With embedded diagnostics, user-friendly touch-screen interfaces, and automatic error alerts, manufacturers can maintain high standards of quality assurance with minimal intervention.

Environmental considerations are also taken into account. Modern machines often support the use of recyclable or biodegradable packaging films, aligning with the growing demand for eco-friendly solutions in feminine care. Combined with low-energy consumption motors and compact design, the sanitary napkin packaging machine offers both economic and environmental advantages.

The importance of hygiene in feminine products cannot be overstated, and the sanitary napkin packaging machine sets a new benchmark for safety, efficiency, and quality. In a competitive market where brand reputation is closely tied to product trust, adopting such cutting-edge machinery is no longer optional—it’s essential.

As consumers continue to seek reassurance through quality and cleanliness, investing in automated, zero-contact sanitary napkin packaging machine solutions ensures that manufacturers not only meet expectations but also exceed them—today and into the future.